Products Overview

Overview Manual Systems

Overview of Manual Flying Probe Test Systems

Overview of Manual Flying Probe Test Systems

ATG flying probe tester products are renowned for speed, accuracy, versatility and ease of use. The world leading position has been achieved by continueous development and pure dedication to enhancement requests from customers all over the world, feedback from the field service engineers and taking part in worldwide Design for Testability conferences in order to allow our customers to manufacture PCB's with the certainty that a reliable test can be performed using our equipment.

A5-Neo - Developed for small batches Rigid & Flex boards

A7 - Ideal for mix of small & larger batches

A7-16- Large Format Flying Probe Test System

A8 Plus - High Speed - Fine Pitch Flying Probe Test System

A8-16 - High throughput Flying Probe Test System for production panel and complex server boards

All information subject to change without notice!

For more information, visit the website or send us your information request.

Flying Probe Test System for Substrates

Overview of Substrate Flying Probe Test Systems

Substrates with structures down to 10µm and several hundred thousand test points per panel require specific solutions for

- scanning

- capacitance measurement

- high accuracy and temperature Management

S2 Plus - Developed for HDI & Substrate Products

S2-16 Plus - Developed for HDI & Substrate Products

S3 - High End Substrate Flying Probe Test System

S3-8 - High Speed - High End Substrate Flying Probe Test System

All information subject to change without notice!

For more information, visit the website or send us your information request.

Automatic PCB Flying Probe Test Systems

Overview of Automatic Flying Probe Test Systems

With high labor costs in Europe and the US, and the surge in labor cost in Asia, automated test solutions are in demand. Automated systems also improve traceability and reduce operator mistakes.

The combination of automation with high throughput test systems is perfect to extend the usage of Flying Probe Testers to mid size production/sample volumes.

Our customer has the choice between three different automation units. Each unit has its own characteristics of throughput, flexibility and product handling. All automation units are prepared for lights out Operation.

A7-a - Fully automatic Flying Probe Test System

A8-a - Dual Shuttle Flying Probe Test System

A8-16a - Automatic High Speed - Fine Pitch Flying Probe Test System

All information subject to change without notice!

For more information, visit the website or send us your information request.

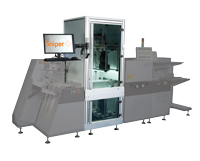

LM800 Picomat II

Octal Density Grid Test System

The fixture tester LM800 is the test solution for big quantities for HDI products. The system can be equipped with the optical alignment system SNIPER to compensate product offsets.

KEY FEATURES

- Extra high density

- Accuracy

- Economical Efficiency

- Automatical Optical Alignment

- Low Ohm Testing

- High throughput universal fixture test System with octal (35 mil) test point density

- Test area up to 244mm x 325mm (9.6″ x 12.8″)

- Optical alignment system SNIPER optional

MACHINE FEATURES

TEST FIELD SIZE

Maximum (X x Y): 244mm x 325mm (9.6" x12.8') - Smaller field sizes available upon request

Maximum (X x Y): 244mm x 325mm (9.6" x12.8') - Smaller field sizes available upon request

BOARD HANDLING

- Maximum board size: 284mm x 365mm (11.2” x 14.4”)

- Minimum board size: 50mm x 50mm (1.97” x 1.97”)

- Minimum board thickness:

- Manual testing 0.1mm ( 0.0039”)

- Automatic testing 0.6mm (0.023”) and warpage < 10mm

- Maximum board thickness: 8mm (0.315”)

TEST POINTS

- 35 mil (800 test points / inch²)

- 98,304 one side

- 196,608 both sides

TEST PARAMETERS

- Isolation test voltage (optional, depending on test method):

- 35V to 250VDC

- 15 V to 250VDC

- Isolation threshold: 100 kΩ to 100 MΩ

- Continuity threshold :10Ω to 10 kΩ

- Embedded resistor measurement: 1Ω to 10kΩ

GENERAL CONNECTIONS

- Data input format: IPC-D-356A

- Network connection: Ethernet, TCP/IP

- Power Supply: AC 400 V [3 / N / PE AC 400 V] 50 / 60Hz

- Compressed air: connecting preassure 6 bar

- Temperature: 20°C to 25°C

- Relative humidity: 40% to 60%

- Machine weight: about 1000kg

DATA PREPERATION

- External generation of drill-files, test-files and object files for fault location is done in ADAM II

- Required data formats for data preparation: Gerber Extended Gerber IPC-D-356A .dpf-data ODB++ Mask & drill data

- Fault location and verification is done in CAR II or on an atg flying prober

OPTIONS

- Retractable guide rails

- 4-wire measurement 10mΩ to 100Ω

- Board thickness control

- PCB offset detection module SNIPER including feedback frames

RELATED PRODUCTS

All information subject to change without notice!

For more information, visit the website or send us your information request.