Zero-Defect Tooling

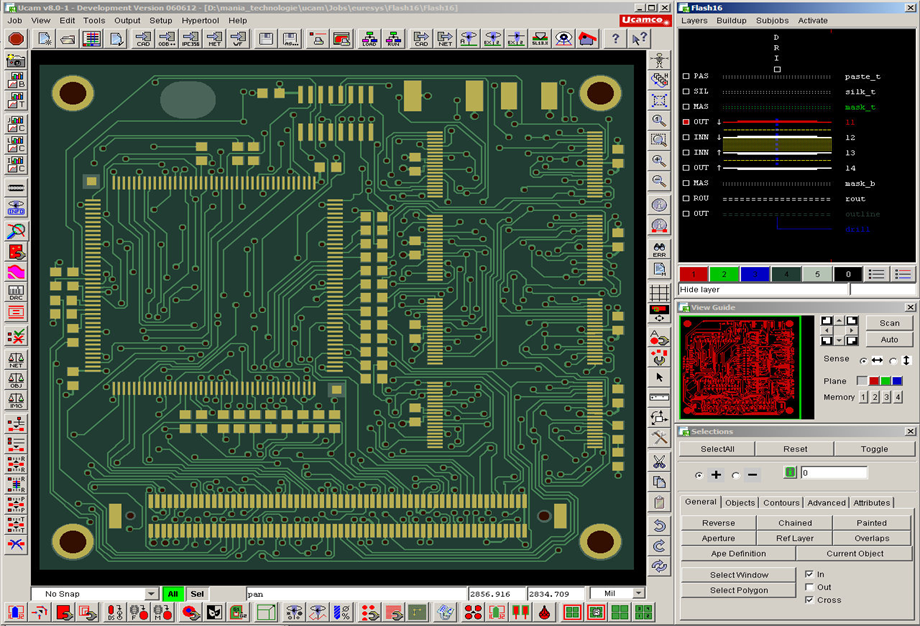

UCAM Cam++ captures not just layout data but also netlist information, customer specifications, mechanical drawings and manufacturing rules in a single smart engineering database. From the database launch automatic DRC and DFM checks without vendor limitations. Optimize plant yields using automated DFM routines.

UCAM Cam++ deploys powerful automatic security tools to detect accidental operator errors. For flexible circuitry see our UCAM uFlex Brochure.

INTEGRATION IN EXISTING ENVIRONMENT

We provide our customers with all interfaces, upstream to CAD/DFM, downstream to manufacturing and quality control. UCAM Cam++ outputs fully automated machine-optimized tooling for all industry-standard electrical testers and AOI systems, photoplotters, drilling and routing equipment and direct imagers. Product parameters can easily be uploaded into corporate production management databases, or in various formats for other CAD/CAM systems.

OUT-OF-THE-BOX CAM PRODUCTIVITY

CAM Cam++ is delivered readyautomated with built-in dynamic functionality for a fast roll-out and a fully customized smart workflow. Labor-saving functions include automated board structuring, netlist and test-point generation without manual intervention, & dynamic yield-driven auto-panelization. Working on one job and need to look at others? No need to close down: just use MultiSessionto open as many extra jobs as you need on your workstation.

- Zero-defect tooling for rigid and flex circuits

- 100% integration into existing environment

- Out-of-the-box CAM productivity

- High-level automation – without limits

- Faster production, higher yields

- Enhanced supplier profile

All information subjected to change without notice!

For more information, visit the website or send us your information request.