Input, Identify and output Component data

PreCAM & ENGINEERING

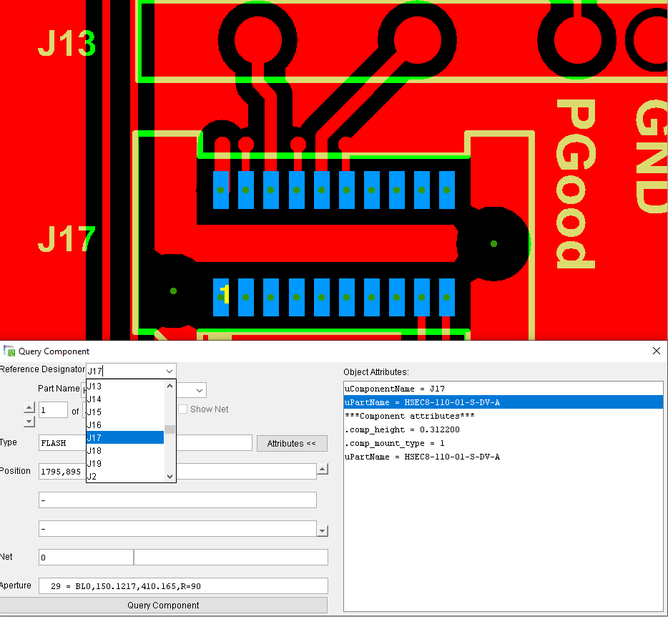

View component types or specific components - Input component data including - Reference designator and Part Name - Pin numbers - Reference net names - Additional component attributes - Generate component BOMs, production docs and Pick&Place files - Trace connections and reference net designators - Trace components back to original schematic.

Assembly Seat

NO

1<

>

A Cloud service by Ucamco

PreCAM & ENGINEERING

It provides a platform for bi-directional communication between the PCB manufacturer, PCB designer and any other party potentially involved in the manufacturing process.It provides access to image data, annotations, questions and answers and keeps a full communication history for traceability and archiving purposes.

Communic8tor

NO

2

<>

server for Auto Input and Design Analysis

PreCAM & ENGINEERING

Integr8tor is the Ucamco's Software Tool bringing the solution for a fully automatic analysis of Design Data Sets presenting you, the user with full comprehensive report of the type of technology & production parameters.

Read More

Integr8tor

NO

3<

>

Zero-Defect Tooling

CAM STATIONS

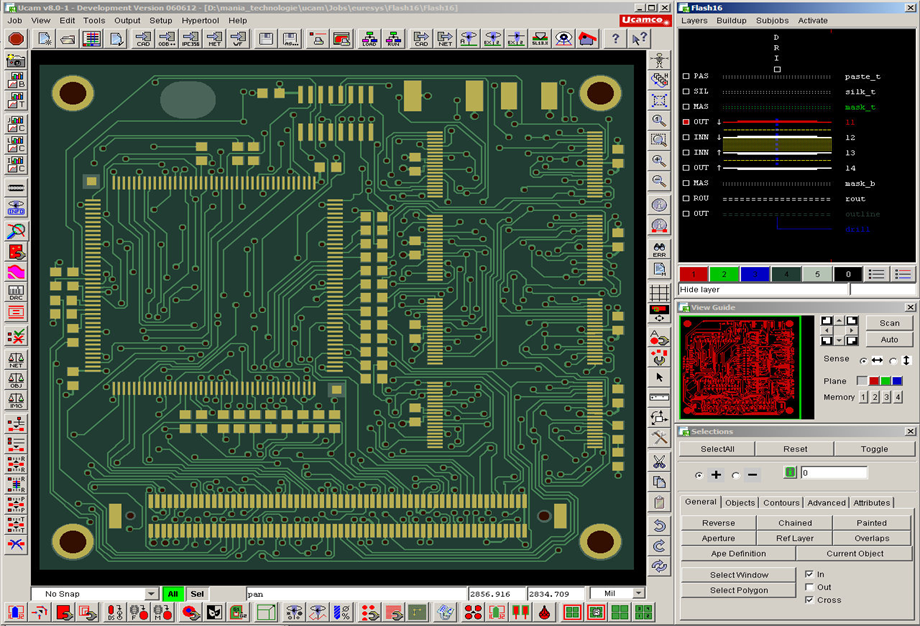

UCAM Cam++ captures not just layout data but also netlist information, customer specifications, mechanical drawings and manufacturing rules in a single smart engineering database. From the database launch automatic DRC and DFM checks without vendor limitations. Optimize plant yields using automated DFM routines.

Ucam CAM++

NO

4

<>

Easy-to-operate User Interface

ELECTRICAL TEST

The clever design of FaultStation3's new interface optimizes every gesture of the person at the controls. Feedback from users shows an increase in throughput of up to 10% on highly complex boards. Whether the operator wants to drive the program from keyboard shortcuts or from a mouse, he finds the functionality he looks for in the place he expects.The central Load Panel gives access to testers and error data.

Ucam FaultStation3

NO

5

<>

Reliable fixtures, shorter set-up time

ELECTRICAL TEST

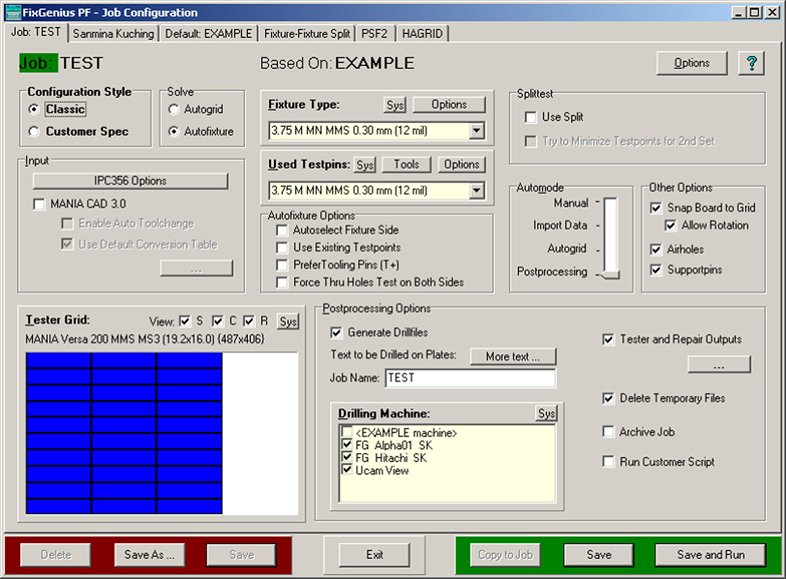

No matter how complex the job is, it is a mere matter of minutes before the test solution is ready. Automated functions save hours of laborious editing.

Ucam FixGenius

NO

6<

>

Advanced Customization Resource

CAM STATIONS

HyperTool is Ucamco's ground-breaking advanced customization resource for UCAM. Unlike C-shell scripts, useful in the main only for commandsequencing, HyperTools are true application extensions to current UCAM functionality.

Ucam HyperTool

NO

7

<>

Seamless Ucam/Polar integration

CAM STATIONS

-Saves up to 15 minutes per job Polar time

-Saves up to 1 hour per job Ucam time

-Only one material database to maintain

-Less errors > Less scrap > Less Costs

Ucam Polar Link

NO

8<

>

required plating thickness

CAM STATIONS

We complemented our existing range of automated 8-Head systems with the launch of a fully automated 16-Head Flying Probe system. The new machine extends the range of applications to larger formats.

Ucam SmartPlate

NO

9

<>

Secure data preperation

CAM STATIONS

Ucam SmartPlot is a productive and secure datapreparation for Ucamco’s PhotoPlotters, such as: SilverWriter and Calibr8tor. SmartPlot imports complete jobs (Ucam, ODB++ and OI5) with all parameters or complete layers with embedded aperture definitions (DPF, MDA and RS-274-X). It merges layers into films, submits films to the plot queue and manages the process. SmartPlot comes standard with the plotter.

Read MoreUcam SmartPlot

NO

10<

>

For innovative and effective solutions

CAM STATIONS

Ucamco's UCAM UFLEX software has been launched in response these challenges. Powerful tool-sets help product engineers develop innovative and effective solutions for cutting-edge designs, while highly flexible automation routines take care of the repetitive and time-consuming manual tasks which hamper engineering creativity.

Ucam uFlex

NO

11

<>