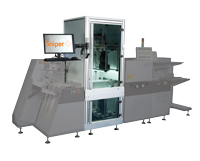

Fully Automated Optical Fixture Alignment System

Fully Automated Optical Fixture Alignment System

The optical alignment system measures the offset between board image top / bottom and the mechanical drilled through-holes. An adjustment frame can move the fixture up to +/- 200 µm against the board layout.

KEY FEATURES

- Fully automated detection of PCB manufacturing tolerances

- Compatible with LM400 and LM800 grid test systems

- 2 telecentric lenses with high resolution cameras

MACHINE FEATURES

Max. Panelsize: 300mm x 300mm (11.81" x 11.81")

Max. Panelsize: 300mm x 300mm (11.81" x 11.81")- Two color Firewire cameras with 5 Mpx

- Compatible with Luther & Maelzer LM400 and LM800 test systems

- Plain image capturing software on Windows PC

- Axial LED lighting

- Double-sided optical survey

- Test system controlled

- Manual width adjustment of conveyor belt

- Manual alignment of telecentric lenses in x- and y-direction

- PCB offset alignment by fixture feedback frame in test unit

TECHNICAL DATA

- Camera monitoring area: 91mm x 76 mm

- Camera resolution: 2448px x 2048px (37 µm/px)

- Repeatability ± 10 µm

- Power supply 230 V / 50 Hz (115 V / 60 Hz), 500 VA

- Weight 320kg / 705lbs

RELATED PRODUCTS

All information subject to change without notice!

For more information, visit the website or send us your information request.