A powerful and intelligent system for controlling and recording scale distortion after bonding and prior to the drill process

The reactive element of the system can be used by Production to improve product yields by accurately displaying drill scaling factors based in real measurement data. Can save otherwise scrap batches by intelligently analysing and displaying the actual effects of drill scaling.

Maximise profit.

Improve technical capability;

- Annular ring

- Higher layer count

- Increased density

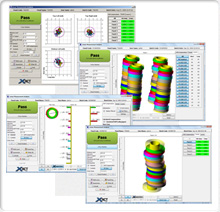

LINEAR

Understand the fundamental causes of registration error in your manufacturing processes.

The intuitive graphical interface allows users to see the systematic and variable errors present in the product.

Determine post lamination scale error and compensate the drill program dynamically. Reduce batch variability. Improve batch yield immediately by drill scaling optimisation

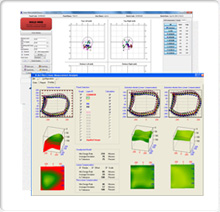

Unique and powerful solution enabling the manufacturer to accurately quantify non linear registration errors and provide optimum non linear compensations.

The system provides the most powerful analysis engine currently available to interpret measurement data and provide easy to understand 3D graphical representation of the contours of distortion.

NON LINEAR

Unique and powerful solution enabling the manufacturer to accurately quantify non linear registration errors and provide optimum non linear compensations.

The system provides the most powerful analysis engine currently available to interpret measurement data and provide easy to understand 3D graphical representation of the contours of distortion.

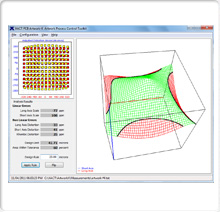

ARTWORK

- Better artwork control = improved production yields.

- Fast and easy toolkit providing complete process control for artwork films.

- Verify your plotter calibration.

- Analyse your true artwork capability and start improving production yields.

- Unique graphical contour display.

- Non linear graphical representation.

- Trend artwork errors over time by lot, material, plotter and process parameters.

All information subject to change without notice!

For more information, visit the website or send us your information request.