The JetRite Legend Printing System eliminates the need for conventional processes as Screen-Printing and Photo-Lithographic processes. The conventional processes are extremely labor intense and require skilled operation. The JetRite also eliminates the need for many expensive consumable materials such as Artwork plotting, developing, setting up screens, cleaning etc.

THE PROCESS

- Before each printout the print heads get cleaned automatically to ensure stable printout results. Using 3 point alignment to compensate board translation, rotation and scaling.

- Automatic Panel height measurement using a laser unit & Printhead height adjustment.

- Automatic Alignment using customer defined fiducial positions, it is possible to define one set of standard fiducial positions per board size and side.

- During actual printing Jetrite also creates:

- Global logLogs general events (user log-in, configuration changes, error messages etc.). Beside the message text each log entry contains the event's timestamp and the logged-in user.

- Job logs. Additionally there exists a log for each single job, storing information about events related to this job.

- Print protocol. The print protocol contains detailed information about each printout (timestamp, lot and board no., print settings, printing time etc.).

- On The Fly Tack Curing by means of UVpattern-zoom.

- Possible to print second (other) side immediately.

- Standby:

- After an adjustable amount of time (typically 45 minutes) of inactivity the machine automatically enters standby mode.

- In Standby the machine becomes suspended as far as possible by switching of the heating of ink and heads.

- The Standby mode assures regular cleaning of ink system and print heads. After exiting standby the machine needs about 30 seconds to get ready to print.

- Print head cleaning:

- Optionally a more intense cleaning can be automatically done after a configurable time interval, allowing to adjust the cleaning actions for the different customers' demands and conditions.In case of persistently faulty printouts the operator can invoke an intense print head cleaning by clicking a button on the user interface.

ADVANTAGES

- From CAM (Gerber) to Print in <5 minutes

- No waste of hazardous materials

- Deskilled operation

- Extremely economic use of Inks

- Accurate automatic patter alignment to panel

- Serialisation printing capabilities

- Compact System

- Reliable Printheads

- Industrialised (proven) Agfa Ink

- Maintenance Friendly

- Lowest Cost of Operation

MACHINE FEATURES

SUPERIOR PRINT QUALITY

- Multiple Colours - on the Fly

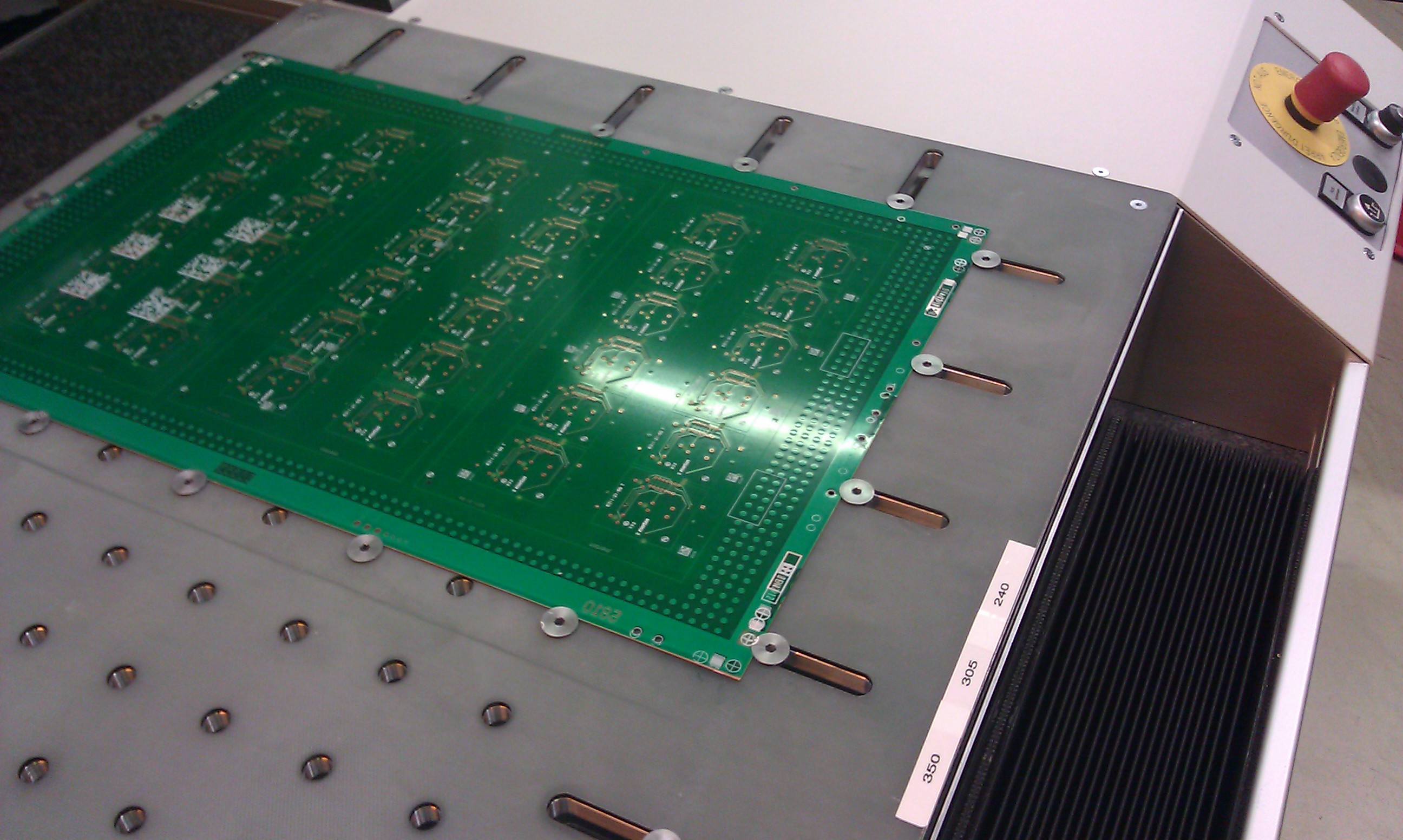

- Multifunctional Clamping System

- UV-LED Curing on the Fly

- Maximum Panelsize: 650 * 550mm (25.6" * 21,6") - larger on request

- Minimum Panelsize: 100 * 150mm (4" * 6")

- Printing area: 610 * 762mm (24" x 30")

- Resolution: 360 / 720 dpi / 1440dpi

- Colours 1 or 2 per system

- Choice between white, yellow, black

- Minimum text height: 0.5mm

- Minimum line width: 100µm

- Droplet size: 14pl

- Print head to media distance: adjustable, typically 1.3mm

TABLE CLAMPING

- Panel "Mushroom" holders

- Easy operating

- Easy modifying of position

- Optional Vacuum Table with Side Clamping

All information subject to change without notice!

For more information send us your information request.