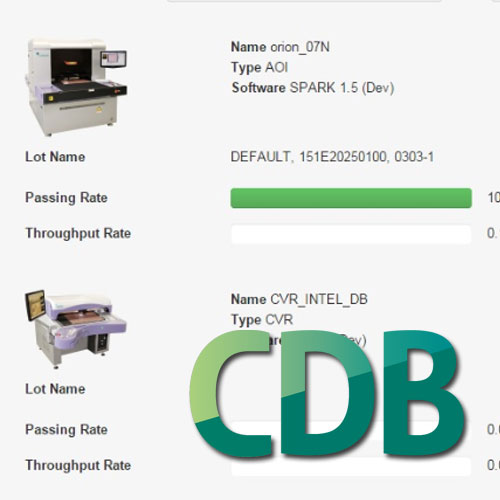

CDB and CDBIC are data management systems integrated with CIMS

equipment. They are designed for quality and process control of the entire

PCB inspection production cycle while also serving as real time defects

inspection production cycle while also serving as real time defects

classification system.

CDBIC adds another layer of control by tracing individual defective units

across multiple layers and processes. It also integrates AVI data into the

data management process combining it with the inputs from AOI.

VVS: Virtual Verfication System

VVS consists of a server that pulls the images of defects from every CIMS AOI and then sends them to VVS stations for sorting and filtering. In VVS stations, those images are shown to operators who then quickly remove non-critical and non-functional calls while passing only images that are most likely to represent true defects directly to CIMS Verification & Repair stations (CVR).

VVS consists of a server that pulls the images of defects from every CIMS AOI and then sends them to VVS stations for sorting and filtering. In VVS stations, those images are shown to operators who then quickly remove non-critical and non-functional calls while passing only images that are most likely to represent true defects directly to CIMS Verification & Repair stations (CVR).

As a result, subsequent visual verification of actual panels with CIMS CVR focuses mostly on marking and repairing of the real defects rather than skipping over non-critical and non-functional defects.

>> AOI Markets

>> IC Substrates: 5 -15 micron nominal line/space

>> HDI PCB: 15 - 30 micron nominal line/space

>> MLB PCB: 30 - 100 micron nominal line/space

>> Flex, Rigid Flex, R2R: 5 - 15 micron nominal line/space

>> Flex, Rigid Flex, R2R: 15 - 30 micron nominal line/space

>> Special Applications

>> Add-ons

>> Technology

All information subject to change without notice!