Single Sided Vacuum Filling of (via) Holes

Main application: This machine is designed to fill holes in printed circuit boards with conductive or non conductive pastes. The hole filling can be applied in Via Holes and in Blind Holes. The VHF-300V is also ideal for Selective Hole Filling applications.

The Filling Proces

- Boards are horizontally suspended by the clamping system

- Door is closed and the chamber is made vacuous (about 20 sec.)

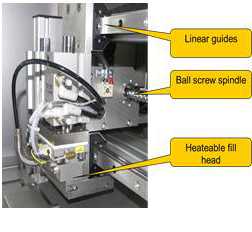

- The filling process starts with the paste by piston being pressed out of a cartridge into the bores by compressed air and the squeegee moved all over the pcb

- The contact pressure, filling pressure and squeegee speed are adjustable

- The movements of the X- and Y-axis are controlled by servo motors

Specifications

- Maximum Panel size: 610 x 762mm

- Panel thickness: 0,15 – 8mm

- Plant depth: 1470mm

- Plant width: 1525mm

- Plant height: 1420mm

- Weight: approx. 720kg

Advantages

- One Step process

- No risk of air bubbles inside the holes

- The paste is stored in a changeable cartridge

- Different head´s for different panel sizes

- All process parameters are part of the recipe

- The touch panel display allows up to 50 recipes to be stored

All information subject to change without notice!