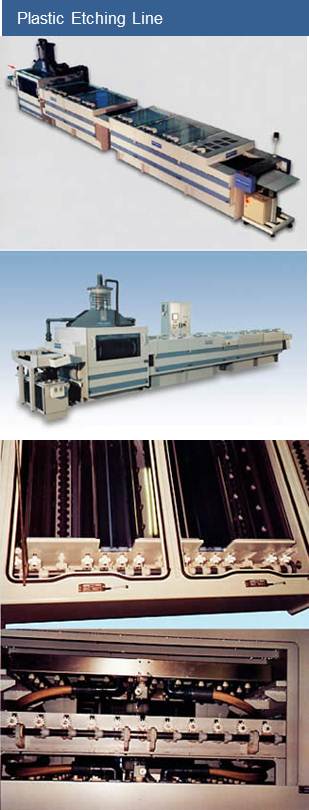

Etching module

High rigidity construction, Pvc supporting structure and titanium components.

Including

- Etching chamber with 4 spraying sections (2 upper + 2 lower sections)

- Supporting titanium frame, providing for spraying manifold oscillation

- The oscillation of the manifolds is controlled by an inverter drive and can be adjusted with regards to the conveyor speed

- Automatic regeneration of the etching solution : the exhausted solution is drained while fresh solution is replenished by back cascade flow from the last "anti-pollution" section

- A dedicated densimeter,precise and reliable, complete with long life probes controls the regeneration process

- The spraying chamber is separate from the solution tank: very few ammonia vapours in case of service

- Moreover the side location of the solution tank prevents deformation of the spraying chamber.

Technical data

- Conveyor width: 635mm

- Conveyor height: 900mm

- Adjustable conveyor speed: 0.5 - 4 m/min

- Max board size: 635mm

- Min board size: 200 x 250mm

- Min board thickness: 0.8mm (option 0.1 core)

- Max board thickness: 4mm (option: higher thickness)

- Overall machine sizes: 9390 x 1600 • 5730 x 1600mm

- Overall control cabinet dimensions: 1200mm x 450mm x 1900 h.

- Pressurized air 4 bar: 100 NL/min

- Water consumption: 400 • 600 dm3 /h

- Installed power: 380V - 3 phase - 50 Hz: 35 • 20Kw

- Net weight: 1.700kg

For more information, visit the website or send us your information request.