Prototype & Low Volume, Fast Processing

- 9 Cells

- Cell Size: 1118 * 610mm (44 * 24")

- Multiple Panel loading per Cell

Plasma treatment uniformity is a key operational feature in desmear and etchback applications for HDI, flexible and rigid circuit board manufacturing technologies.

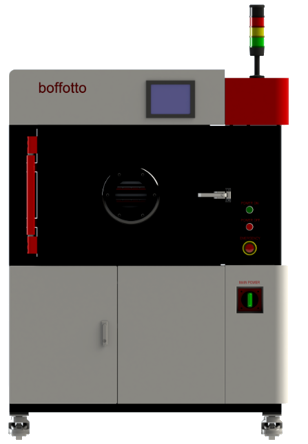

P15V-E9S PLASMA TREATMENT SYSTEM

- The P15V-E9S system platform is completely self-contained, requiring minimal floor space. The vacuum system, plasma chamber, control electronics, and 40 kHz power supply are housed in a single enclosure. Full front and rear access allows for convenient service to all interior components. The pump is positioned on rollers for easy removal. No side access is required allowing for even greater floor space savings.

- The P15V-E9S system incorporates the best of Boffotto's market leading technology combined with novel application specific technology development based on our greater than 20 years of experience. Through extensive research and development, the P15V-E9S system presents unique vacuum and gas flow technology, new electrode designs, and superior temperature management. The careful balance of these critical design elements and process recipe parameters delivers a system that creates the most uniform PCB treatment for key applications like desmear and landing pad cleaning.

- All our P15V system's superior performance capabilities are complemented by very attractive low-cost-of-ownership aspects. The system features a very compact and service-friendly design. The vertical loading concept and the use of easy loading carts minimizes any idle time which generates high levels of productivity. The fast vacuum pump down and greatly enhanced process cycle times further add to the throughput and productivity of the system.

- Equipped with a touch-screen PC Operator Interface, the P15V-E9S system provides a wide breadth of control capability and data collection. Unlimited recipes can be stored for easy switching of plasma processes from batch to batch. Password protection ensures that no unauthorized entries can be made.

ADVANTAGES

- High throughput of HDI, flexible and rigid panels for maximum production flexibility

- Accommodates larger panel sizes within a small footprint to consume minimal floor space

- Faster units per hour (UPH) processing to meet today's demanding manufacturing schedules

- Low CF4 gas consumption for desmear applications contributes to the lowest cost of ownership in its class

- Patented system technologies produce superior process uniformity at high throughputs

MACHINE FEATURES

- Aluminium Chamber Construction

- Vacuum Chamber: 1105L

- Real-Time Temperature Controlled Electrodes

- Oxygen Service DRY Pumping Package with 65 CFM Pump and 2600CFM Blower

- PE II - 10,000 Watt, 40 KHz RF generator with automated tuning network

- Gas Control of up to 5 Mass Flow Controllers with low gas alarms

- Optimized gas consumption for cost-effective use of gasses such as CF4

- Multiple Rack Assemblies for optimized loading of Rigid and Flex Panels

- Fully Integrated High Resolution Touch Screen

- No hazardous waste disposal

OPTIONS

- H2 Processing Integrated Safety Control & dedicated Mass Flow Controllers

- Wide Range of Frames available for easy and secure Flex Panel loading & processing

RELATED PRODUCTS

All information subject to change without notice!

For more information, visit the website or send us your information request.