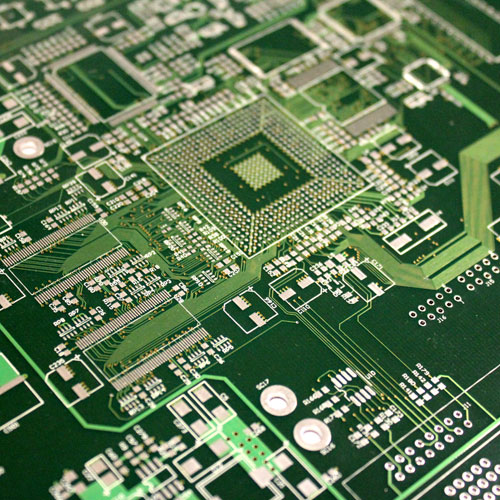

High Density Interconnect

HDI PCB are widely used in high end applications such as cellphones, tablets, computers and other devices that are typically characterized by space constraints. Moreover, production process of HDI PCB tends to be more complex compared to mainstream multi-layered boards (MLB). It also involves complex processes such as build-up and laser drill via which often require optical inspection of its own.

HDI PCB are widely used in high end applications such as cellphones, tablets, computers and other devices that are typically characterized by space constraints. Moreover, production process of HDI PCB tends to be more complex compared to mainstream multi-layered boards (MLB). It also involves complex processes such as build-up and laser drill via which often require optical inspection of its own.

CIMS is the leading inspection solutions supplier for HDI PCB manufacturers who produce boards for the top makers of high end electronic and communication devices. Our Phoenix series AOI systems are build with the most advanced optics, hardware and algorithms enabling unparalleled detection of the type of defects that often occur during HDI production.

>> Learn more

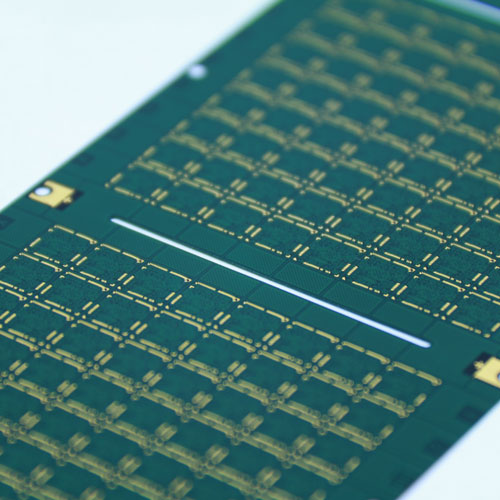

IC Substrates

IC Substrate serves as a connector between IC chip and the PCB. It is, in effect, a highly miniaturized version of a printed circuit board itself. In other words, IC Substrates bridge the nano-scale world of a semiconductor device (IC) and the micron-scale of a PCB. Besides the mechanical support and protection for the chip, IC Substrates are also required for heat dissipation as well as signal and power distribution.

IC Substrate serves as a connector between IC chip and the PCB. It is, in effect, a highly miniaturized version of a printed circuit board itself. In other words, IC Substrates bridge the nano-scale world of a semiconductor device (IC) and the micron-scale of a PCB. Besides the mechanical support and protection for the chip, IC Substrates are also required for heat dissipation as well as signal and power distribution.

CIMS offers series of AOI and AVI solutions for manufacturers producing wide variety of IC Substrates. Our Phoenix AOI and Unicorn AVI systems are designed to inspect even the most advanced IC Substrate products with down to 4 micron line and space widths. Phoenix Nano, Micro and Maxima series can be further enhanced with additional metrology capabilities.

>> Learn more

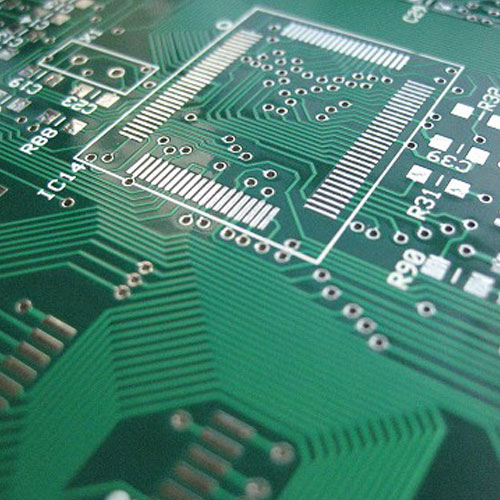

Multilayer PCB (MLB)

Multi-layer PCB is the most common type of printed circuit boards produced with two or more layers of circuit patterns stacked vertically, each separated by an insulating medium. The connectivity between the layers is typically achieved by drilling through the laminated board and copper plating the drilled holes. MLB PCB are widely used in all types of consumer and industrial electronics. They can range in complexity from fairly simple to highly advanced boards such as those used in automotive and server applications.

Multi-layer PCB is the most common type of printed circuit boards produced with two or more layers of circuit patterns stacked vertically, each separated by an insulating medium. The connectivity between the layers is typically achieved by drilling through the laminated board and copper plating the drilled holes. MLB PCB are widely used in all types of consumer and industrial electronics. They can range in complexity from fairly simple to highly advanced boards such as those used in automotive and server applications.

CIMS supplies the range of cost effective solutions for this market that ensure fast and reliable inspection of all types of PCB materials and designs. Our systems can be used for inspection of bare copper, photo-resist, finished boards as well as photo-tools such as silver halide artworks and glass masks.

>> Learn more

Flex and Rigid Flex PCB (FPC)

Flex PCB (FPC) is a technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrates. Flexible electronic assemblies may be manufactured using identical processes used for rigid printed circuit boards, allowing the board to conform to a desired shape, or to flex during its use. Rigid flex printed circuit boards use a combination of flexible and rigid board technologies in an application.

Flex PCB (FPC) is a technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrates. Flexible electronic assemblies may be manufactured using identical processes used for rigid printed circuit boards, allowing the board to conform to a desired shape, or to flex during its use. Rigid flex printed circuit boards use a combination of flexible and rigid board technologies in an application.

Our solutions for flex and rigid flex PCB inspection are based on advanced imaging technology developed for various types of HDI, IC Substrates and MLB. Since FPCs come in wide ranges of trace widths, CIMS offers a family of dedicated AOIs that can accommodate all this variety. In addition, we provide automated material handling solutions for roll-to-roll (R2R) types of FPC.

>> Learn more

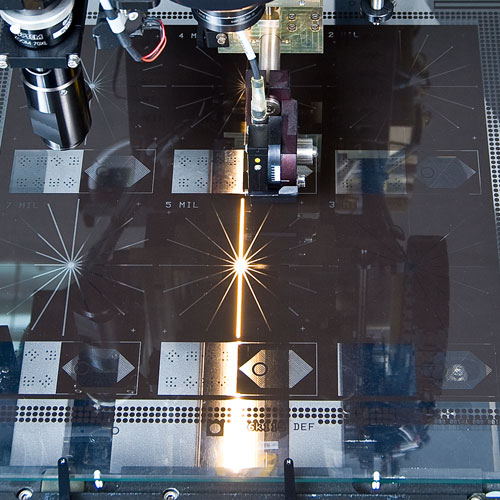

Special Applications

Special applications cover various types of inspection and quality control measures that are not typically part of the conventional AOI cycle. One such example would be our custom made solution for laser via dimple inspection which combines CIMS 3D metrology capabilities with high resolution AOI system.

Special applications cover various types of inspection and quality control measures that are not typically part of the conventional AOI cycle. One such example would be our custom made solution for laser via dimple inspection which combines CIMS 3D metrology capabilities with high resolution AOI system.

CIMS advanced optical inspection technology is also applied to wide variety of applications including those outside the traditional PCB market. Inspection of touch screen is one of the areas where such technology is used by touch screen manufacturers looking to increase yield, reduce manual visual inspection operations as well as improve the quality of the final product.

>> Learn more

>> IC Substrates: 4 -15 micron nominal line/space

>> HDI PCB: 15 - 30 micron nominal line/space

>> MLB PCB: 30 - 100 micron nominal line/space

>> Flex, Rigid Flex, R2R: 5 - 15 micron nominal line/space

>> Flex, Rigid Flex, R2R: 15 - 30 micron nominal line/space

>> Special Applications

>> Add-Ons

>> Data Management

>> Technology

All information subject to change without notice!