AOI Systems

Overview Inkjet Printing

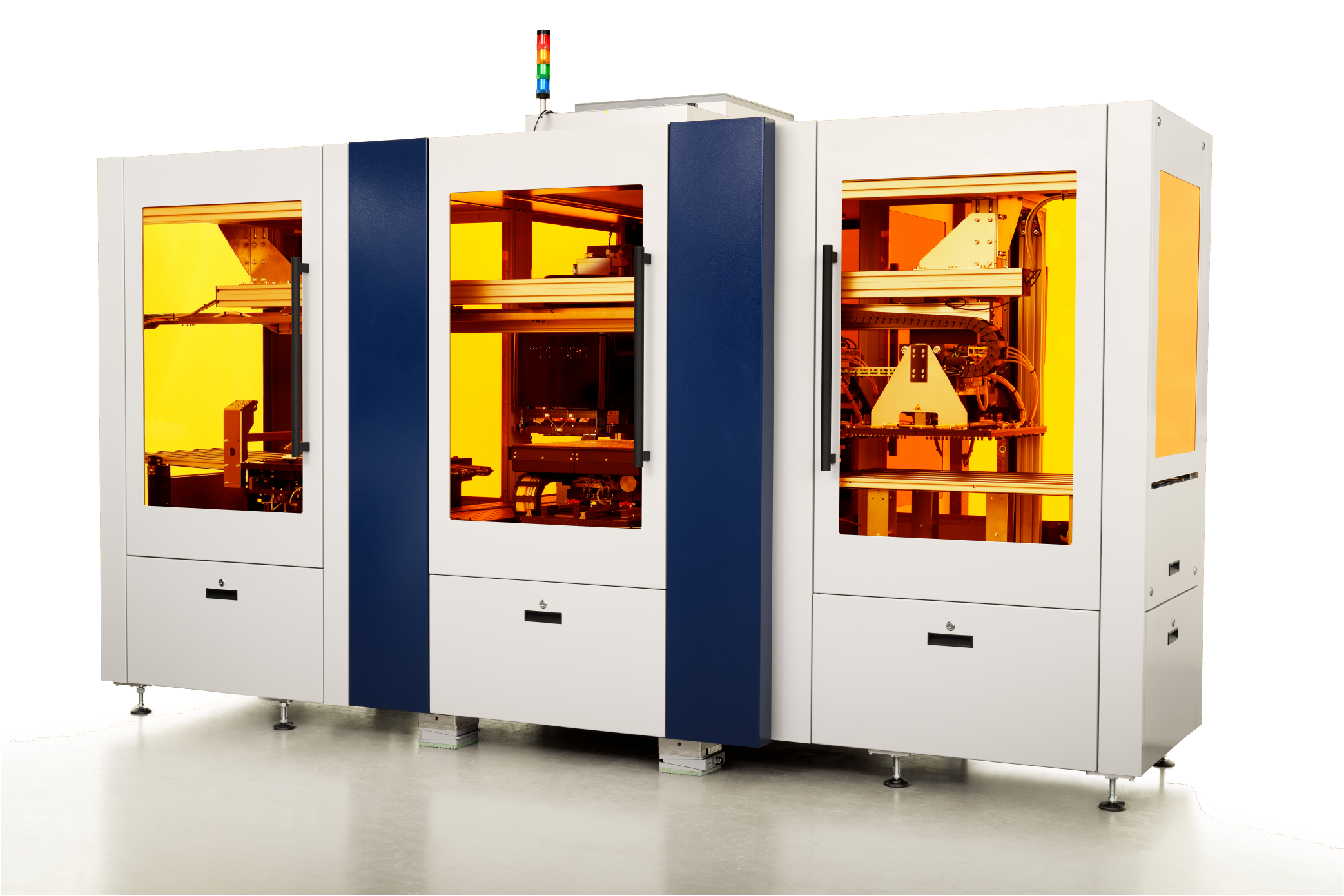

PiXDRO JETx Soldermask

PCB Solder Masking

PCB Solder Masking

Digital inkjet printing for applying solder mask on PCB boards has many significant benefits. That is why PCB manufacturers and material suppliers are transitioning towards direct printed solder mask.

Simplified Process Flow

Compared to the traditional solder mask process, the number of process steps is reduced to three in the inkjet-based process. Pre-treatment remains crucial for good adhesion. The inkjet printer then applies the solder mask material and uses UV curing so the boards come out tack-free. Post-curing concludes the process. This simplification saves capital equipment, labor, process chemicals and waste, and reduces handling and the buildup of yield problems. It also cuts the total time to finish a PCB board – a key point in today’s fast-moving electronics business.

ADVANTAGES

It is a selective coating technology: material is only deposited where required. This reduces material consumption and avoids the challenge of removing surplus solder mask material

It is a selective coating technology: material is only deposited where required. This reduces material consumption and avoids the challenge of removing surplus solder mask material- No risk of removing small solder dams between IC contacts

- Inkjet allows different surface finishes, layer thicknesses and materials. Finally, inkjet has the ability to accurately align and scale the print image to the board

- Inkjet has the ability to accurately align and scale the print image to the board

- Additive and cost-effective solder mask deposition, eliminating photo processes

MACHINE FEATURES

- Alignment accuracy: <2 µm using automated fiducial alignment

- Layer thickness: 30-80 µm, can be varied over the board to reduce material consumption

- >10 µm solder mask thickness on copper

- Solder mask openings: down to 100 µm

- Edge roughness: 20 µm

- Line-space: 75-75 µm

All information subjected to change without notice!

For more information, visit the website or send us your information request.

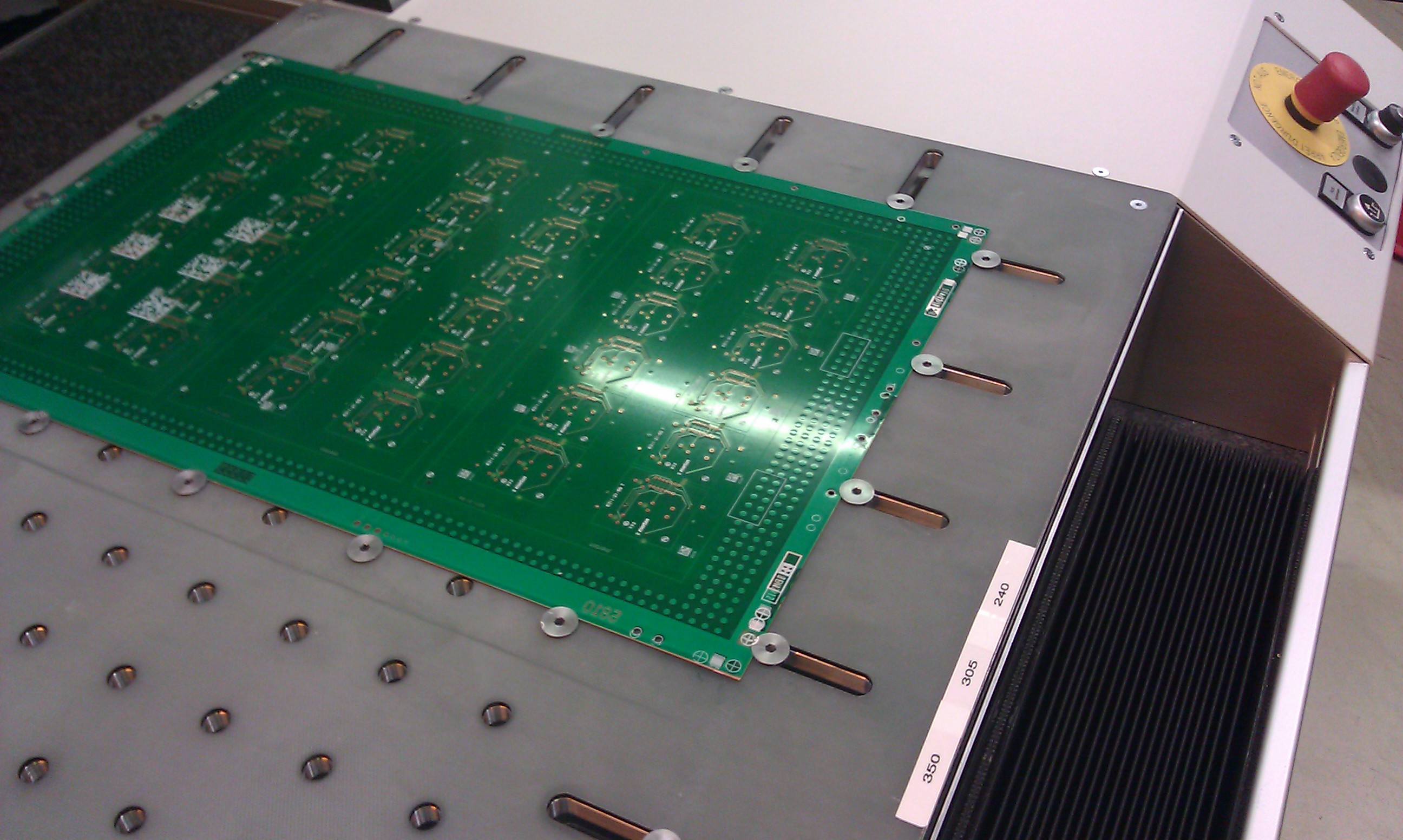

JetRite Legend Printing System

The JetRite Legend Printing System eliminates the need for conventional processes as Screen-Printing and Photo-Lithographic processes. The conventional processes are extremely labor intense and require skilled operation. The JetRite also eliminates the need for many expensive consumable materials such as Artwork plotting, developing, setting up screens, cleaning etc.

THE PROCESS

- Before each printout the print heads get cleaned automatically to ensure stable printout results. Using 3 point alignment to compensate board translation, rotation and scaling.

- Automatic Panel height measurement using a laser unit & Printhead height adjustment.

- Automatic Alignment using customer defined fiducial positions, it is possible to define one set of standard fiducial positions per board size and side.

- During actual printing Jetrite also creates:

- Global logLogs general events (user log-in, configuration changes, error messages etc.). Beside the message text each log entry contains the event's timestamp and the logged-in user.

- Job logs. Additionally there exists a log for each single job, storing information about events related to this job.

- Print protocol. The print protocol contains detailed information about each printout (timestamp, lot and board no., print settings, printing time etc.).

- On The Fly Tack Curing by means of UVpattern-zoom.

- Possible to print second (other) side immediately.

- Standby:

- After an adjustable amount of time (typically 45 minutes) of inactivity the machine automatically enters standby mode.

- In Standby the machine becomes suspended as far as possible by switching of the heating of ink and heads.

- The Standby mode assures regular cleaning of ink system and print heads. After exiting standby the machine needs about 30 seconds to get ready to print.

- Print head cleaning:

- Optionally a more intense cleaning can be automatically done after a configurable time interval, allowing to adjust the cleaning actions for the different customers' demands and conditions.In case of persistently faulty printouts the operator can invoke an intense print head cleaning by clicking a button on the user interface.

ADVANTAGES

- From CAM (Gerber) to Print in <5 minutes

- No waste of hazardous materials

- Deskilled operation

- Extremely economic use of Inks

- Accurate automatic patter alignment to panel

- Serialisation printing capabilities

- Compact System

- Reliable Printheads

- Industrialised (proven) Agfa Ink

- Maintenance Friendly

- Lowest Cost of Operation

MACHINE FEATURES

SUPERIOR PRINT QUALITY

- Multiple Colours - on the Fly

- Multifunctional Clamping System

- UV-LED Curing on the Fly

- Maximum Panelsize: 650 * 550mm (25.6" * 21,6") - larger on request

- Minimum Panelsize: 100 * 150mm (4" * 6")

- Printing area: 610 * 762mm (24" x 30")

- Resolution: 360 / 720 dpi / 1440dpi

- Colours 1 or 2 per system

- Choice between white, yellow, black

- Minimum text height: 0.5mm

- Minimum line width: 100µm

- Droplet size: 14pl

- Print head to media distance: adjustable, typically 1.3mm

TABLE CLAMPING

- Panel "Mushroom" holders

- Easy operating

- Easy modifying of position

- Optional Vacuum Table with Side Clamping

All information subject to change without notice!

For more information send us your information request.

About Adeon

At Adeon we believe that it is the quality of our work that placed us in our current position, and quality is what we try to improve with everything we do. European PCB manufacturers are often challenged to produce many different designs and technology levels every day. This makes it challenging to select and provide equipment that is capable of doing that. Our goal is to offer the best service and support against affordable rates to the highest standards to help our customers to stay at the forefront of technological developments.

Latest News

- 01 October 2021 ACB Group invests in new Flying Probe System

- 07 January 2021 CCI Eurolam SA acquires Adeon Technologies BV

- 10 November 2020 Exception PCB purchases Ledia Direct Imager