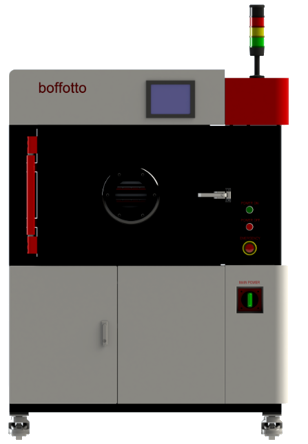

Adeon Technologies offers a complete range of Boffotto Plasma Systems for Printed Circuit Board processing.

As European market leaders in the field of plasma we understand the need for flexibility and versatility. The keywords for plasma batch processing of Printed Circuit Boards are "Process Uniformity". Adeon offers to all Plasma systems it supplies a free of charge "Life Long Application Support", meaning we will provide the best possible recepies and parameters for the Plasma Batch Process based on materials loaded and process type required as for example:

- Desmear & Etchback

Improving reliability. Plasma effectively removes the residual resin and other contaminants in multi-layer printed circuit boards to vastly improve reliability.

The mechanical drilling of vias in multi-layer PCBs creates a residual resin that smears along the walls of the vias, impeding metalization of the electrical connections. After drilling, resin removal from inner layer posts is required to ensure reliable electrical contact. Traditional methods of etching and desmearing are often not effective for today’s multi-layer board designs due to the capillary effect present with wet chemicals, and the limitations related to the use of advanced board materials. In contrast, plasma effectively removes epoxies, polyimides, high Tg blends, mixed materials, and other resins in standard and high aspect ratio panels.

- Surface Activation

Inner layer preparation: Plasma alters the topography and wettabilitty of inner printed circuit board layers to promote adhesion Cover-coated inner board layers that contain flex materials with unsupported polyimides have smooth surfaces that are difficult to laminate. Plasma alters the topography and wettability of the inner layers to promote adhesion by allowing thin layer processing through use of flex clips. Other chemical processes are not as effective: it is difficult to control the amount of material removed, and unsupported polyimides are inert to most chemicals.

- Carbon removal

Plasma treatment removes carbon from both conventional through-hole board vias and blind vias. Laser-formed vias often produce a carbon by-product that prohibits electro-less adhesion. Carbon that mixes with epoxy or polyimide resin and becomes trapped in the vias must be removed prior to metalization. Plasma cleaning removes the carbon from both conventional through-hole board vias and blind vias typically used on boards where component space is restricted.

- Cleaning Descum

Plasma treatment removes resist residue from PCB inner layers and panels without affecting the circuit pattern. It also removes residual solder mask bleed from lands for better bonding and solderability. Resist residue sometimes remains after developing fine pitch circuitry. If the residue is not removed prior to etch, the board can short circuit. Plasma effectively removes resist residue from inner layers and panels without affecting the circuit pattern. It also removes residual solder mask bleed from lands for better bonding and solderability.

- Surface - PTFE Activation

The Boffotto plasma process can modify fluoropolymer surfaces and desmear resins to prepare hole walls for electro-less copper or direct metalization

Surface activation for double-sided and multi-layer fluoropolymer through-hole boards is necessary to increase surface wettability. Chemical processes do not have the flexibility to treat non-stick materials and other resins mixed in the same panel. However, a single plasma process can modify fluoropolymer surfaces and desmear resins, effectively preparing hole walls for electro-less copper or direct metalization.

All information subject to change without notice!

For more information, visit the website or send us your information request.

R2R Plasma Treatment System

R2R Plasma Treatment System