Planarizing of excess Resin/Paste after the Hole Filling Process is a critical process. Its succes depends on a variety of parameters:

- Type/Brand of Resin

- Resin Bump Height

- Resin Bump hardness

- Copper thickness on the panel surface

- Copper Surface flatness & variation

- Prototype or volume production

- Operator Skills

PCB manufacturers need to carefully consider these variations when chosing the type of Planarization system. It occurs regularly that PCB manufacturers use a combination of different systems for different variaties of filled via's. ADEON Technologies BV offers a range a Planarization systems in partnership with Mass GmbH and Pola & Massa srl.

Mass - SV-200-WV

Mass - SV-200-WV

Semi-Automatic Planarizing

with Vacuum Table

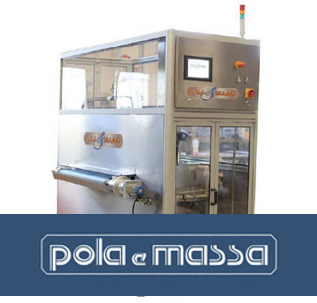

Pola & Massa - Evo-3000

Pola & Massa - Evo-3000

Automatic Single Brush

Capable of Selective Area filling

Pola & Massa - Pem-650

Pola & Massa - Pem-650

Multiple Brushes

Higher Volume production

All information subject to change without notice!