Assembly Seat

Input, Identify and Output Component data

* View component types or specific components

* Input component data including

* Reference designator and Part Name

* Pin numbers

* Reference net names

* Additional component attributes

* Generate component BOMs, production docs and Pick&Place files

* Trace connections and reference net designators

* Trace components back to original schematic

* Determine pin numbers and component orientation

EASY INPUT OF COMPONENT INFORMATION

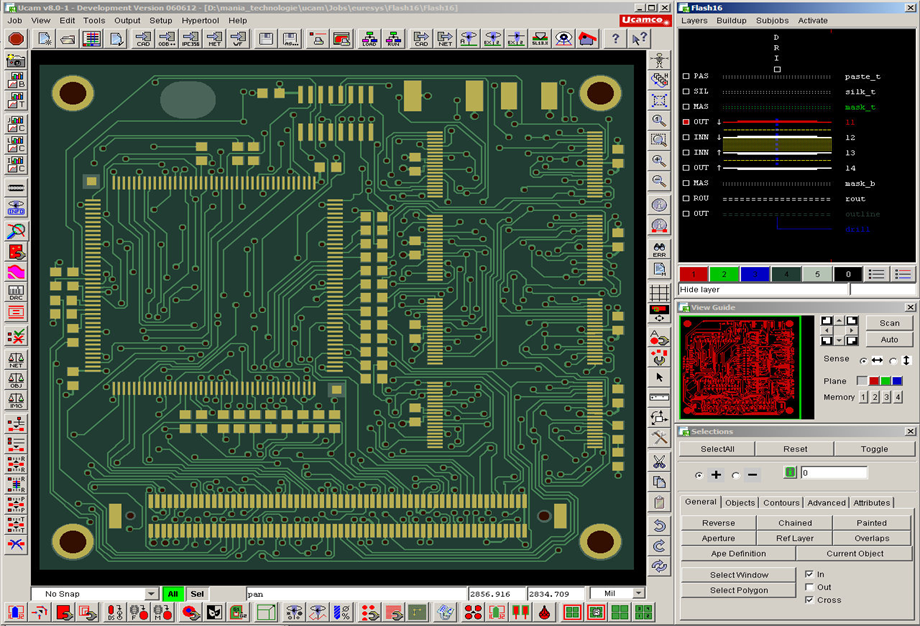

Input is simple using the existing methods. No need for additional steps. New “component” layers are auto-matically added after selecting job and layers. The layers can be viewed or used to reference components

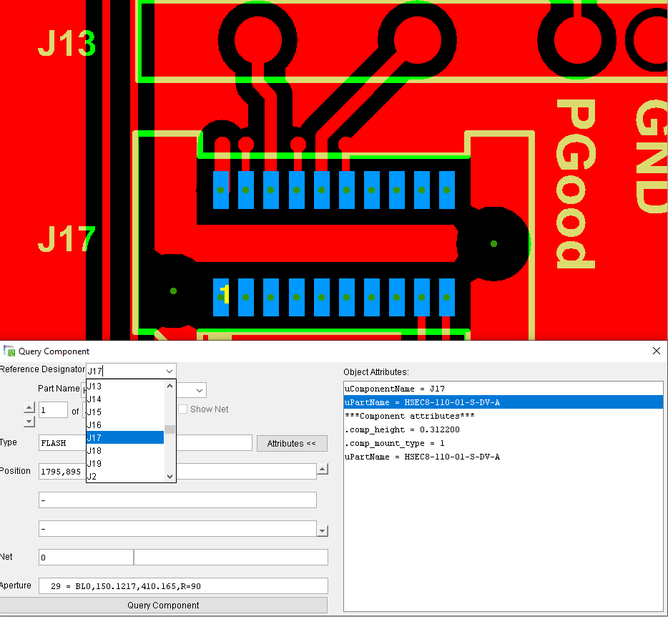

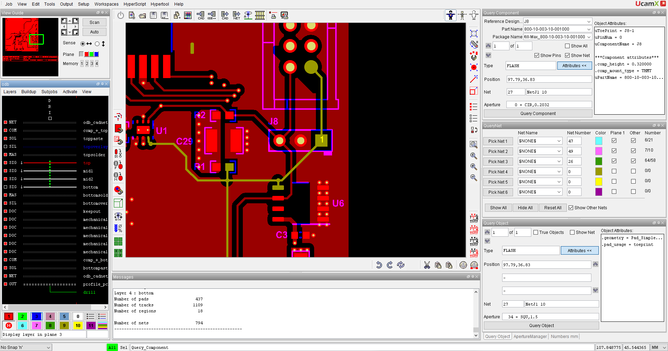

QUERY COMPONENT AND PACKAGE

New Query Component interface ensures uncomplicated selection of components. Selections can be based on Reference Designator, Part Name or Package Name. Alternatively simply click on a component and get detailed information on all the different component descriptions in one go.

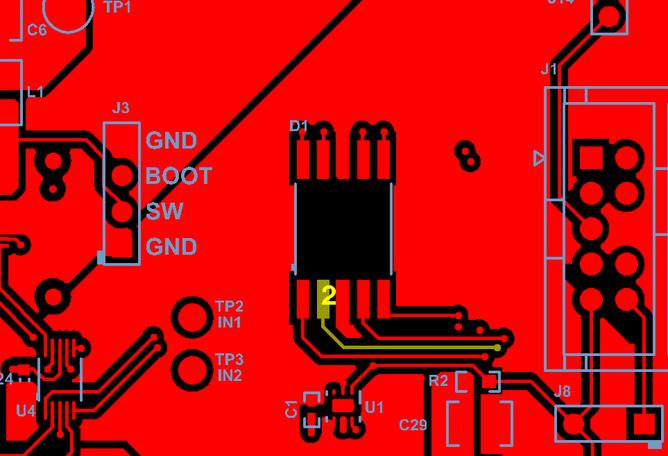

TRACE COMPONENTS BACK TO ORIGINAL SCHEMATIC

TRACE COMPONENTS BACK TO ORIGINAL SCHEMATIC

Compare net names of component pin numbers to schematics ensuring there are

no conflicts or connection issues.

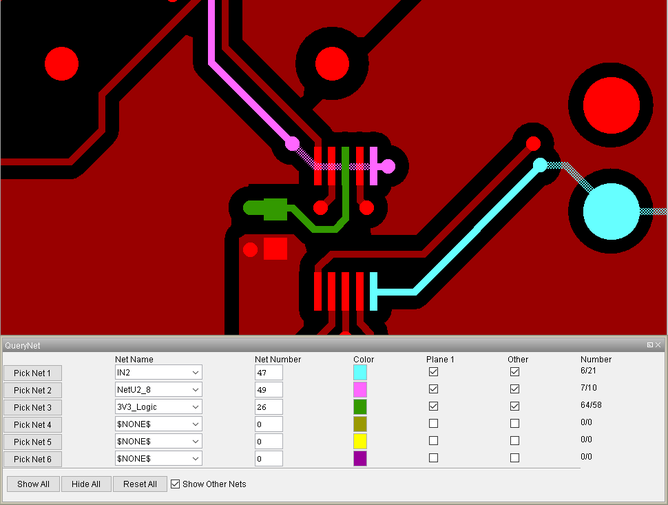

QUERY PIN AND REFERENCE NET

Hassle-free identification of pin numbers, land size or annular ring.

In addition reference Net Names and Net Numbers are available for each component.

GENERATE BOM'S AND PRODUCTION DOCUMENTS

Custom BOMs and other custom production documentation created easily

using Visual Hyperscript.

All information subjected to change without notice!

For more information, visit the website or send us your information request.

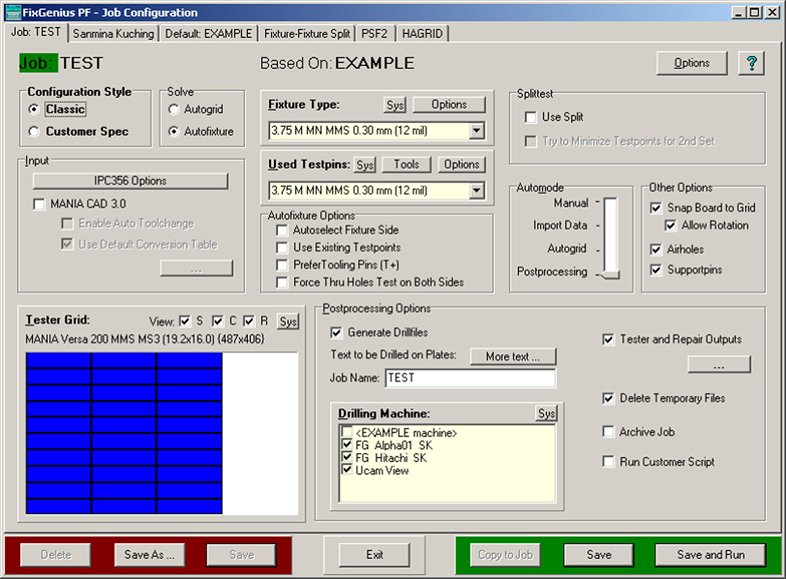

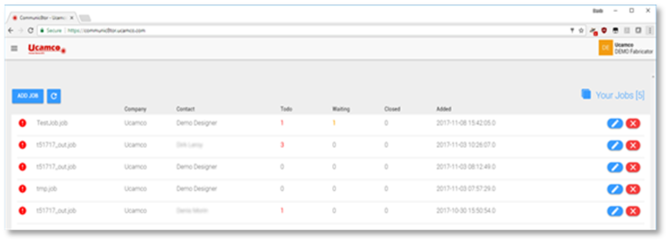

HyperTool is Ucamco's ground-breaking advanced customization resource for UCAM. Unlike C-shell scripts, useful in the main only for commandsequencing, HyperTools are true application extensions to current UCAM functionality. Like much of UCAM's core development HyperTools are written in Java™. The use of Java™ ensures seamless integration between UCAM and your HyperTools as well as unlimited access to all UCAM functions.Unlimited customization UCAM's world-beating graphic automation delivers a wealth of customization options "out of the box". Java™ HyperTool adds unlimited customization possibilities to maximize your CAM productivity and reliability.

HyperTool is Ucamco's ground-breaking advanced customization resource for UCAM. Unlike C-shell scripts, useful in the main only for commandsequencing, HyperTools are true application extensions to current UCAM functionality. Like much of UCAM's core development HyperTools are written in Java™. The use of Java™ ensures seamless integration between UCAM and your HyperTools as well as unlimited access to all UCAM functions.Unlimited customization UCAM's world-beating graphic automation delivers a wealth of customization options "out of the box". Java™ HyperTool adds unlimited customization possibilities to maximize your CAM productivity and reliability.