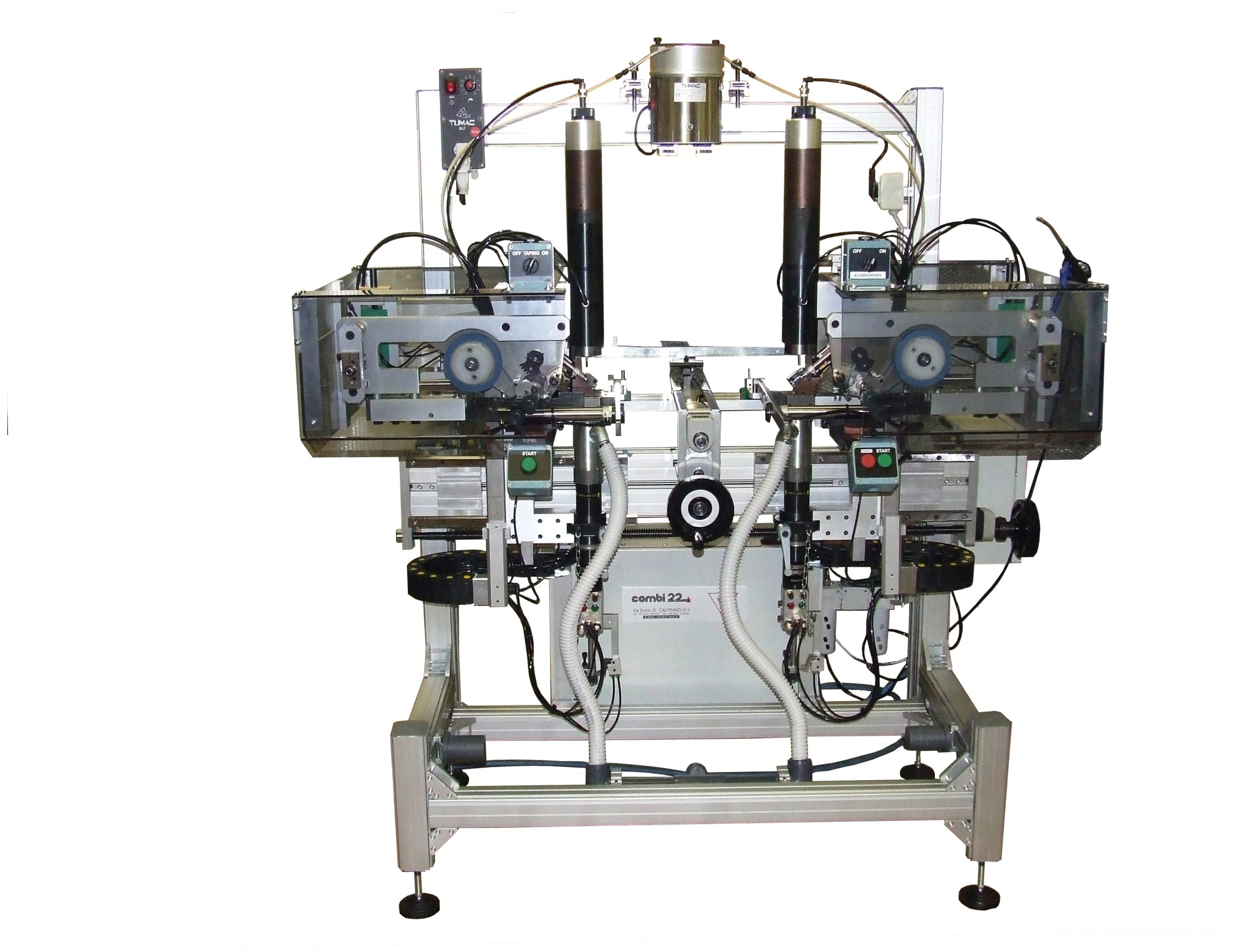

Combi22

Drillstack preparation

Pinning & Taping machine for stack preparation before the PCB drilling process. Executes simultaneously the pinning and taping operation on the shortest edges (pin edges) and with a second cycle only the taping on the longest edges.

ADVANTAGES

- Solidity

- High Productivity

- Simple setup : 3 hand wheels for pin distance (X axis), stop on end on the Y axis and distance between tapes with digital measure reading.

- Only pneumatic operation (high reliability)

OPERATION

- Drilling, Pinning & Taping simultaneously on pin sides

- Additional Taping only on long sides

- Spindle/Cylinder positioning by Handwheel using accurate Mechanical Counters

- Pneumatic securing of Spindle/Cylinder position

- Hydraulic Brakes for Z-Axis damping feed (fast approach, regular feed, no exit burr)

- Automatic Pin Feed

- 4 Taping Heads (2 left, 2 right) with adjustable distances betweentapes

- Adjustable Tape Length on Entry Material

MACHINE FEATURES

- Max machine dimension: 1760 x 1450 x 750mm

- Min. machine dimension: 1300 x 1450 x 550mm

- Pins feeding: Automatic

- Pins length: 18 - 20mm

- Pins diameter: 3.00 - 3.17 - 4.00 - 5.00mm

- Stack dimension: Min 280 x 350mm - Max 720 x 600mm

- Holes distance and Y position stop with continuous regulation by hand wheels (easy measure reading by mechanical counters).

- Hydraulic brakes for infeed absorber (quick approaching, regular feed and absence of burr on return feed).

- SUGINO drilling units (High quality supplier and worldwide service)

- Air pressure feeding group extremely accessible for inspection and cleaning

WORKING CYCLES

- Drilling – Pinning (D/S PCB)

- Pinning – Taping (multilayers)

- Taping

RELATED PRODUCTS

All information subjected to change without notice!

For more information, visit the website or send us your information request.