AOI for inspection of flex and rigid-flex with min line/space down to 10 µm.

AOI for inspection of flex and rigid-flex with min line/space down to 10 µm.

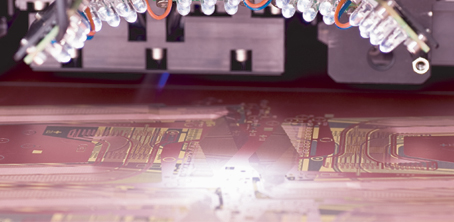

Phoenix FLEX/Maxima, CIMS latest generation of AOI system, is designed to support high volume manufacturing of fine line flex and rigid-flex PCB. It is capable to scan down to 10 µm line/space width technology.

The system’s state of the art optical technology Prisma™ is designed to provide flexible light coverage with maximum contrast in order to support high resolution image acquisition at high scanning speed. Optimized performance is achieved by combining sharp high resolution image with customizable detection algorithms.

Equipped with the state-of-the-art image acquisition and advanced software capabilities, the Phoenix product family is renown for its exceptional detection achieved with lowest possible false calls rate.

Phoenix FLEX/Maxima is powered by Spark™ – an innovative cross-platform detection engine.

Basic functionalities include

Basic functionalities include

- Designed for flexible PCBs of all types

- Enhanced by Microlight™ - New Optical Technology

- Powered by Spark™

- CRS/PX – CIMS Reference Station for Spark

- Shortest setup time

- High precision robust mechanical base

- Advanced open architecture software

System highlights

- New linear motors for smooth & silent motion

- Micro technology Automated vacuum table

- Prisma illumination 64 bit based firmware

- Powerful processors to handle high density PCB

- Compatible with front or back L/U automation

- Simple and quick setting for new jobs

Optional Features

Optional Features

- +2DM metrology - panel dimensions measurement

- +2CD metrology - 2D measurments of circuit elements

- +3DH metrology - 3D measurements of circuit's element height

- +3DP metrology – 3D profiling of circuit element

- LDI - laser drill inspection

- CDB/CDBIC - defects classification and virtual defects mapping

- VVS - virtual verification system

All information subject to change without notice!