AOI verification station for HDI and multi-layer PCB with min line/space down to 25 µm.

AOI verification station for HDI and multi-layer PCB with min line/space down to 25 µm.

CVR 100

CVR 100

CVR-100, CIMS verification station, is designed to support high volume manufacturing of HDI and multi-layer PCB. It is optimized for verification of 25 ~ 100 µm line/space width technology.

The system’s state of the art illumination enables to clearly distinguish and accurately classify all types of defects while allowing for convenient defect marking and repair. Robust mechanics and powerful hardware ensure high throughput and efficiency.

CVR-100’s user friendly interface and superior ergonomics are designed for convenient and easy operation that requires only minimal training. It is also fully compatible with CDB and CDBIC – CIMS defects and scrapped units data management system.

CVR-100 is compatible with all CIMS AOI as well as third party AOR (automated optical repair) stations.

Optimal illumination design

Optimal illumination design

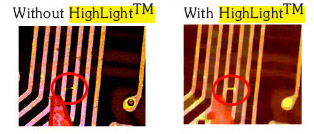

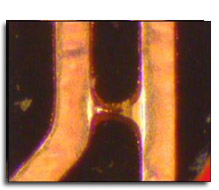

HighLightTM illumination consists of LED Reflective, diffusive and low diffusive light that ensures optimal light coverage of the inspected area, making all detected defects (including shallow-shorts and other very fine defects) visible and clear.

Adaptive light calibration mechanism

HighLightTM automatically adapts the light intensity and coverage to suit different material and defect types without user intervention, achieving optimal image contrast of the defect.

Defect-Enhancer™ software (Optional)

The patent pending image-processing algorithms analyze the original defect's image and HighLight™ the defect to the operator.

System Highlights

- Multimple illumination configurations

- Ergonomically designed

- Stationary vacuum table

- Optimized defect-to-defect movement

- Clear defect image and adjustable video light

- Variable zoom and automated calibration

Optional Features

- Auto-marker for marking defects

- Barcode reader

- Adjustable monitor arm

- CDB/CDBIC – defects classification and virtual defects mapping

- VVS – virtual verification system

All information subject to change without notice!