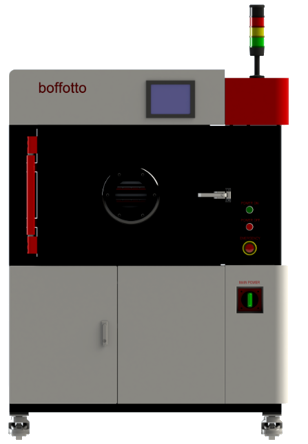

Roll-To-Roll Plasma

R2R Plasma Treatment System

R2R Plasma Treatment System

Designed specifically for roll-to-wire circuit board and roll-type materials. The Use of advanced transmission technology; creating the perfect combination for plasma technoloy.

ADVANTAGES

- Moving rectifying system ensures the accuracy of winding

- 40KHz plasma excitation power supply with enhanced arc control and extremely wide matching impedance

- Constant tension and speed control system

- Magnetic sealing technology to ensure the whole plasma process conduct in vacuum

- Patent chamber design ensures the stability of transmission system in vacuum

- Suitable for 3” or 6” roller materials

- Specifically for FPCB surface cleaning and blind hole desmear and cleaning functions

MACHINE FEATURES

- Material width10~500mm

- Material Thickness ≥ 18um

- Material Thickness ≥ 18um

- Processing Seed 0.1-2.0 M/Min

- Reaction Zone Length 4 M

- Capacity of Material 3” or 6”

- Greatest Diameter of Material 350mm

- Accuracy ±1 mm

- Power 40KHz@5KW

- Etching Uniformity ≥80%

- Vacuum Pump Dry Pump 1178CFM

- Working Area 3.5 * 4.5M

- Loading Height 1.2M

- Gas Channels 4 Channels 4 Gases

- Dry Air 80~100PSIG

- Electricity Requirement 208VAC/100A/3PH/50/60HZ

- Tension Control Range 0N~100N (Can be configured)

- Weight of Machine 4700KG

OPTIONS

- H2 Processing Integrated Safety Control & dedicated Mass Flow Controllers

RELATED PRODUCTS

All information subject to change without notice!

For more information, visit the website or send us your information request.