Mach3Lab ANTARES 700XA

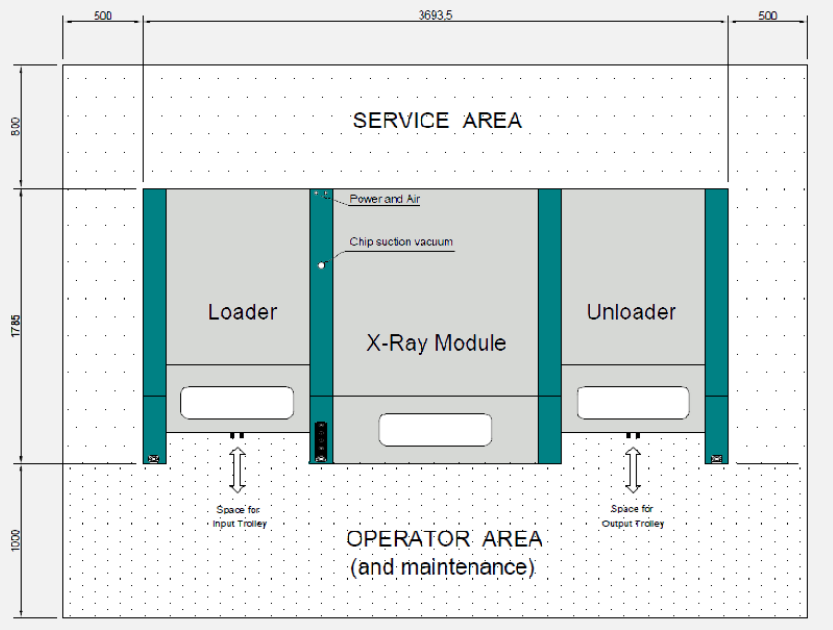

The Antares 700 XA is designed to make reference holes on multilayer panels such as the Antares 700 X, but with the addition of automation for the loading / unloading of the panels, which allows the machine to operate independently after starting the working cycle.

It has the same use as the Antares 700 X but, thanks to the automatic loading and unloading system, the machine is able to work independently until the loading trolley is empty. The panels to be worked are picked up by a robotic arm and fed to the machine. The processed panels are automatically stacked on the unloading trolley. The non-compliant panels are not processed, and therefore unloaded in a rear cart.

Typically the reference holes are used to inset pins, which will be used to clamp the panel with the accurate alignment to the X, Y axes of the drilling machine. To this aim, the reference holes must be executed with best optimization respect to the inner lay-up of the multi-layer panel.

Typically the reference holes are used to inset pins, which will be used to clamp the panel with the accurate alignment to the X, Y axes of the drilling machine. To this aim, the reference holes must be executed with best optimization respect to the inner lay-up of the multi-layer panel.

The process to drill reference holes is made in two steps:

1) In the first step the machine will detect the centers of those targets that have been chosen to represent the internal lay-up. The enlargement/shrinking, due to the previous pressing process, as well as the registration errors are considered.

2) In the second step the programmed holes will be executed in optimized positions based on the detected topography, but at a definite reciprocal distance, as required for pins. The drilling is performed by a pneumatic spindle using a standard drilling tool with ring. (The rotation speed is fixed at 30.000 rpm.) The panel is clamped by vacuum area at the center of table. The table is made by a material that is X-Ray transparent and offers the possibility of inspecting any kind of panels or PCB's in any point, including the vacuum area, which is also X-ray transparent.

ADVANTAGES:

- High flexibility: Arbitrary number of Targets (min. 2) and holes;

- Optimised hole drilling (geometrical error of the board is included into hole position calculation);

- Fast cycle time;

- Also useful for measuring panels only (measuring data can be easily exported);

- Very userfriendly software;

- Automatic unloading system of panels outside specification;

- Full Automation Capability;

TWO SPINDLE VERSIONS:

PNEUMATIC:

- 30.000 rpm fixed speed

- Adjustable descending speed

- Single tool

- 16µm run-out

- Simple & fast tool change

ELECTRIC:

- Max. 60.000rpm

- Position and speed controlled Z-Axis

- Automatic Tool Change (ATC)

- 4 station tool magazine

- Tool Length Device (TLD)

- within 2µm run-out

PANEL FEATURES:

- Max. dimensions: 580 X 660mm

- Min: dimensions: 320 x 320mm

- Panelthickness: 0.3 to 4mm (down to 0.1mm with special vacuum table - optional)

- Target shape: round

- Hole diameter: 1-4mm

- Max hole count: unlimited

MACHINE FEATURES:

- Measuring accuracy: ±15µm

(within a vision area of 640x480mm - 25x19") - Drill on Target accuracy: ±15µm

(round target) - Optimised drilling accuracy: ±18µm

(round targets @ Dt=600mm & Dh=DT 5mm) - Cycle time: 20 seconds

(4 targets + 3 holes) - Productivity: 3 panels/minute 4 targets + 3 holes