PiXDRO Main Features

Digital inkjet printing for applying solder mask on PCB boards has many significant benefits. That is why PCB manufacturers and material suppliers are transitioning towards direct printed solder mask.

Simplified Process Flow

Compared to the traditional solder mask process, the number of process steps is reduced to three in the inkjet-based process. Pre-treatment remains crucial for good adhesion. The inkjet printer then applies the solder mask material and uses UV curing so the boards come out tack-free. Post-curing concludes the process. This simplification saves capital equipment, labor, process chemicals and waste, and reduces handling and the buildup of yield problems. It also cuts the total time to finish a PCB board – a key point in today’s fast-moving electronics business.

Modular Robust Design

Modular Robust Design

- Configurable hardware and software

- Integration of pre- and postprocessing modules

- Choice of base platforms for many applications and substrates

- High accuracy stages

- Choice of industrial printheads

- Connectivity to other processing equipment

Optimal Process Control

- Nozzle and print image inspection

- Automated printhead maintenance

- Flexible process control with flow editor

- MES connection

- User-level controlled access

- Integration in clean and inert enclosure

- Low maintenance

- Easy printhead exchange and calibration

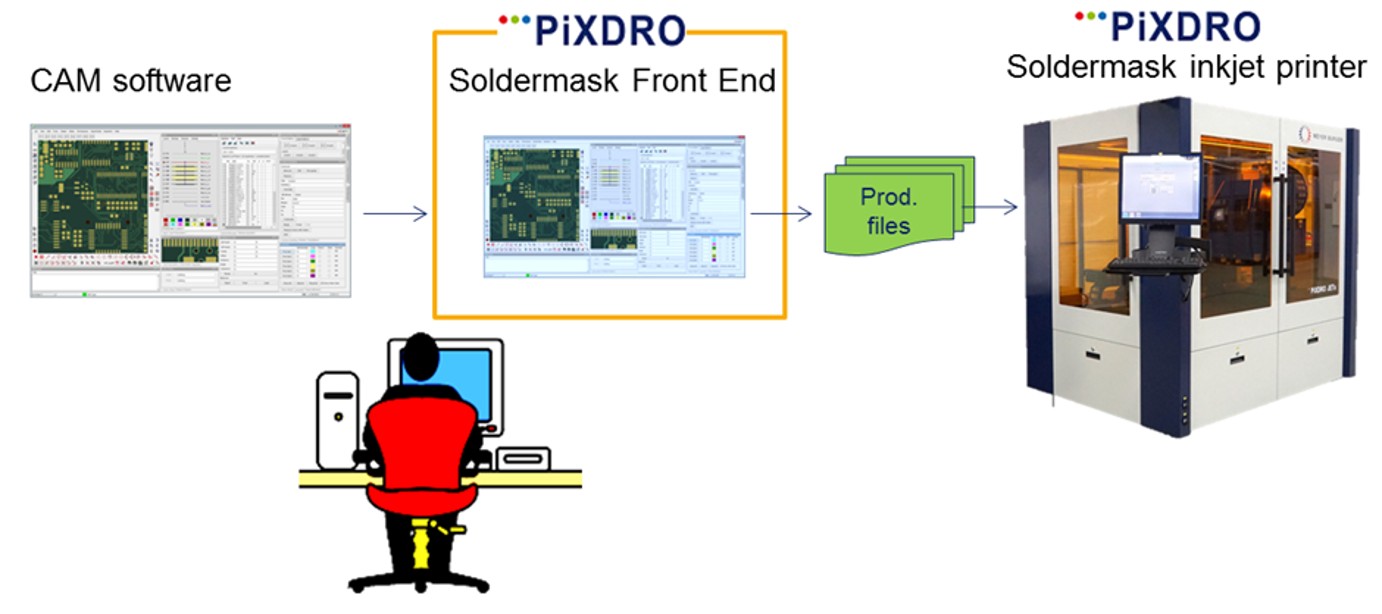

Advanced CAM Interfacing

- Direct link of CAM software ==>> From CAM to print in minutes

- Automated creation and application of all printing data

- Based on design files with all process parameters such as copper and (variable) solder mask thicknesses, drill holes, board and ink materials, pre-treatment, etc.

- Flexible recipe editor

Accurate, versatile and fast

Inkjet printing is very versatile. It can be used for direct material deposition for patterned or homogeneous coatings, from tens of nanometers to tens of micrometers. It can also be used as a 3D printing method.

Because industrial printheads have numerous parallel nozzles, and operate at very high frequencies, inkjet achieves very high throughput. The PiXDRO mass production inkjet printers can hold arrays of multiple printheads, enabling high productivity and flexibility.