GX System:

Self learning Intelligent system

Self learning Intelligent system- Predict scale factors with unrivalled precision

- No coupons – no loss of valuable real estate

- Control and predict distortion

- Powerful, robust & easy to use

- Real time analysis and feedback

- Configurable and customisable

Xplain:

Advanced analysis module providing real time reporting for managers and engineers.

Track Trends over time for:

Track Trends over time for:

- Scale Errors

- Offset (Shift) Errors

- Rotation (Shift) Errors

- Total Positional Error

Viewed by:

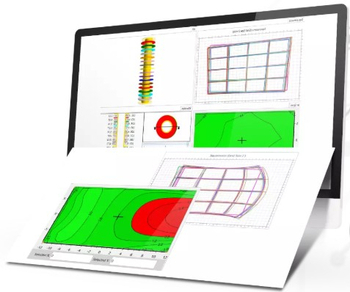

Xsection:

An innovative, non-destructive, engineering-led approach to simplifying and improving registration visualisation by creating Virtual 3D cross sections.

Simple to use, allowing real time analysis of true panel registration, in a fully interactive 360 degree viewing enviroment.

Simple to use, allowing real time analysis of true panel registration, in a fully interactive 360 degree viewing enviroment.

Benefits of Xsection

- Reduce the need for physical micro-sections

- Cost saving

- Time saving

- 3D sectional view available during the measurement process

- Drill scaling can be easily visualised

- Award winning graphical tool

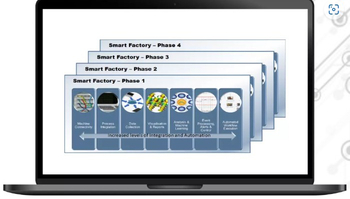

InGeniusX

An agile, flexible, Automation system allowing mass customisation, providing advanced data sharing between machines allowing intelligent in-sight into day to day operations and enhancing communications between people & machines.

Factories that are ‘connected’ enhance productivity, reduce waste and accelerate production, this is achieved through an integrated InGeniusX automated production system.

Factories that are ‘connected’ enhance productivity, reduce waste and accelerate production, this is achieved through an integrated InGeniusX automated production system.

Benefits of InGeniusX

- Production

- Quality

- Cost reduction

- More precise information

- Increased added value

- Enhancing human capacity

- Fully integrated

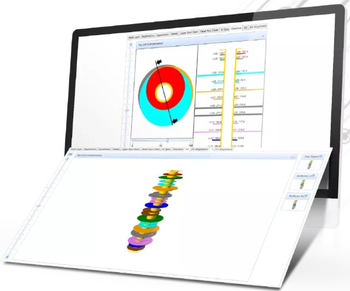

XPC:

Statistical analysis module providing real time reporting for managers and engineers.

A scientific visual method to monitor, control and improve processes by eliminating special cause variation PCB fabrication, a key aid to continuous improvement.

Xpoint Non-Linear

- Visual representation of panel distortionHeat Map – graphical display showing areas most affected by movement

- Ability to pick a point to see registration at that location on the panel