Ucamco Ledia Direct Imaging

Where innovation meets precision

Direct Imaging technology from SCREEN

Direct Imaging technology from SCREEN

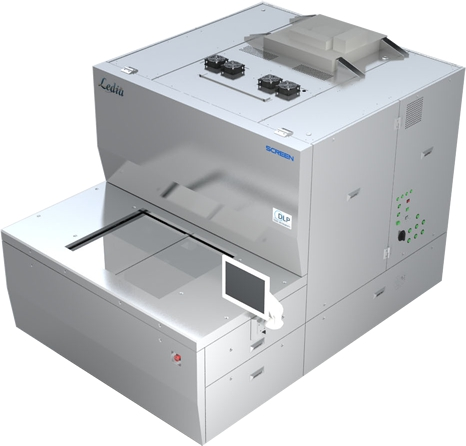

Produced by SCREEN in Japan, a leading PCB equipment manufacturer, and with over 1000 systems sold, the Ledia Direct Imaging system delivers field-proven reliability and throughput. Seven out of ten of the largest global PCB manufacturers work with Ledia. This workhorse is available in Europe exclusively through Ucamco & Adeon, with installations in all European countries. Ledia is supported by Ucamco's local network of highly skilled engineers and with a local spare parts stock, resulting in unbeatable uptime.

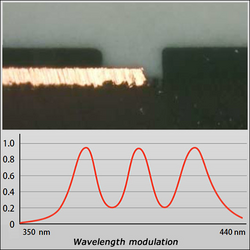

3 simultaneous wavelengths

Ledia’s unique UV-LEDs light source combines two or three different wavelengths simultaneously.

Ledia’s unique UV-LEDs light source combines two or three different wavelengths simultaneously.

==> The wavelength ranges from 350nm to 440nm to diffuse the energy optimally throughout the resist or solder mask.

==> The user can tune each wavelength’s power individually for optimal results on or each material.

==> The result is high throughput and unrivalled quality – 50µm solder mask dams without undercut.

Drop-in

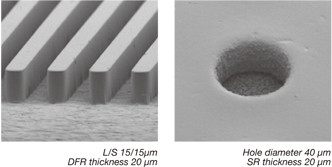

Ultra-fine feature capabilities, a precision auto-focus and an automatic alignment algorithm compensates for substrate distortion. Ledia exposes a wide range of both dry film and soldermask with high-throughput and high-yield. As Ledia delivers top quality even on conventional resists it integrated into existing production environments with minimal hassle by Ucamco’s experienced hardware and software installation team.

Ultra-fine feature capabilities, a precision auto-focus and an automatic alignment algorithm compensates for substrate distortion. Ledia exposes a wide range of both dry film and soldermask with high-throughput and high-yield. As Ledia delivers top quality even on conventional resists it integrated into existing production environments with minimal hassle by Ucamco’s experienced hardware and software installation team.

Data flow automation and integration

Ledia can be integrated with the ERP system, and imminent jobs directly and automatically sent to Ledia.

Serialization

Traceability is an important requirement for industries such as automotive and medicine and it will only grow in the future. Serialization by hand is expensive and error-prone; a growing number of customers no longer accept it. The Ledia software can generate highly-customizable variable images at the time of exposure, both text and data matrix, for serialization or other identification. Configurable individual formatting matches the serialization’s appearance to the customer specification. Serialization can be on the single PCB, the assembly panel or the fabrication panel, or any combination. Fully automate the data preparation through the XML interface.

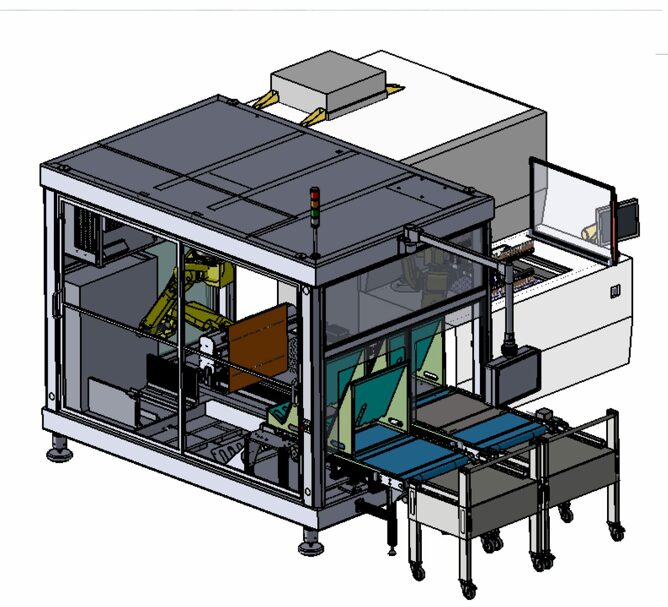

Panel handling automatization

An impressive range of optional automated solutions increases productivity still further.