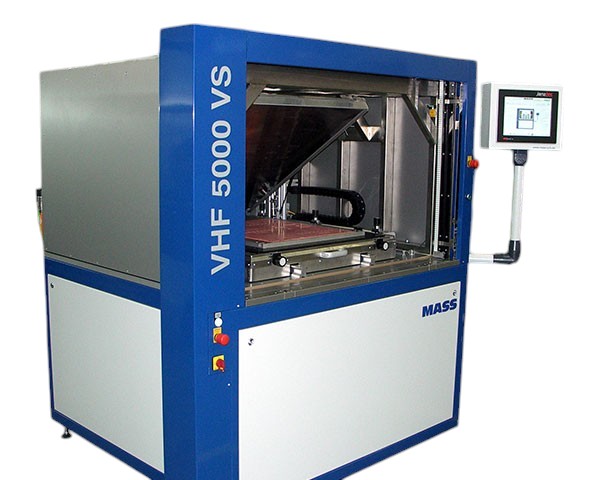

Vacuum Via Hole Filling Machine

This special machine from MASS is designed to fill holes in printed circuit boards with conductive or non-conductive paste. Through holes and blind holes are selectively filled in one pass. A filling head for a specific PCB format is included in the scope of delivery. This filling head is equipped with a heater as standard. Different filling heads and face plates are available for different PCB formats. It can be run with or without vacuum. All process-relevant data is stored in recipes, and the machine can store up to 50 recipes. Frame and cladding are made of stainless steel. MASS has already realized more than 80 VHF machines worldwide.

This special machine from MASS is designed to fill holes in printed circuit boards with conductive or non-conductive paste. Through holes and blind holes are selectively filled in one pass. A filling head for a specific PCB format is included in the scope of delivery. This filling head is equipped with a heater as standard. Different filling heads and face plates are available for different PCB formats. It can be run with or without vacuum. All process-relevant data is stored in recipes, and the machine can store up to 50 recipes. Frame and cladding are made of stainless steel. MASS has already realized more than 80 VHF machines worldwide.

Function and structure of the Vacuum Hole Filling Machine

- Main application: This machine is designed to fill holes in printed circuit boards with conductive or non conductive pastes;

- The hole filling can be applied in Via Holes and in Blind Holes.

- Accurate alignment due to Optical Device and X,Y, T fine tune alignment.

After the printed circuit board has been picked up in a horizontal position at the front by the clamping system, the door is closed and the vacuum process starts. As soon as the vacuum is reached, the filling process begins by pressing the paste out of a cartridge into the holes by means of pistons while the filling head is moved over the circuit board. The contact pressure of the filling head on the printed circuit board is adjustable, as is the paste pressure. The Y-axis is moved by a controllable servo motor. The paste is stored in refillable cartridges.

The following process parameters can be set: Speed and position of the filling head in Y-direction, head contact pressure to the PCB, paste pressure, temperature and vacuum in the vacuum chamber.

MASS builds different variants of via hole filling machines, they differ in the size of the filling head, vacuum function, possibility of selective filling and other parameters.

Specifications:

- Vacuum chamber

- Can be used with conductive and non-conductive pastes

- For through holes and blind holes

- Y axis movement controlled by a servo motor

- Paste is pressed through a screen into the fill holes, using a squeegee blade

- Panel format max. 762 x 610 mm / 30x24”

- Touch-panel PC

Advantage:

Optical Inspection of accurate alignment in X, Y & T